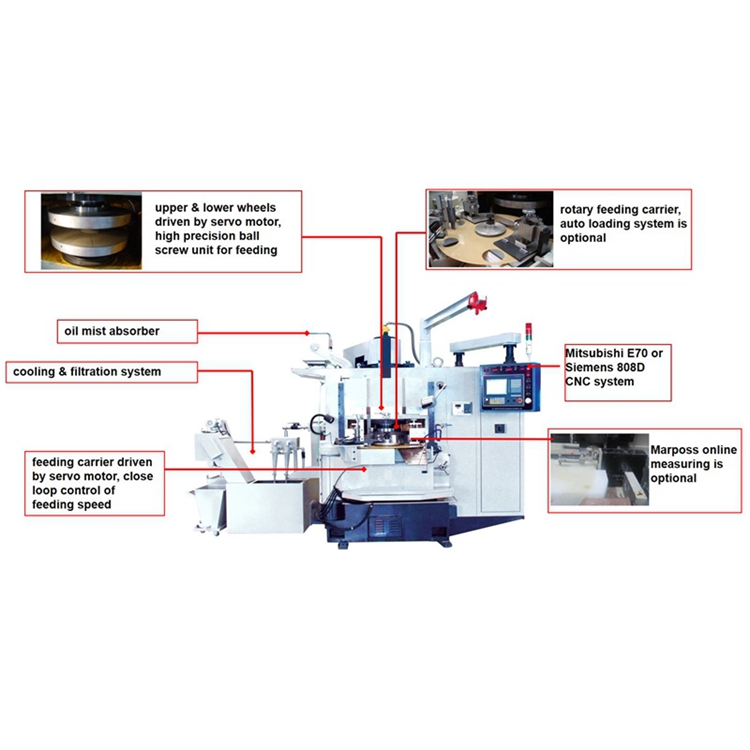

YHDM580 Series Vertical Precision Double Surface Grinder

It is designed for grinding the two parallel side surfaces of the various high precise and thin work pieces with round and abnormal shape, no matter made of metal or nonmetal material, can be processed. Such as bearing, valve plate, seal, oil pump vane, piston ring, etc.

Technical characters

Technical characters:

● CNC system chooses Siemens with friendly HMI and reliable performance.

● The parts’ processing for the upper and lower surfaces is simultaneous with high precision, and without assisted positioning ( such as disks )

● The program about the double disc grinding and wheel dressing control makes it to get high precision grinding.

● Wheel head feed adopts precise ball screw unit. Feeding precision: 0.001 mm.

● Wheel head spindle is driven by converter, 150-950r/min.

● The motor of the feeding carrier adopts converter control; the speed is 1-10rpm.

● The coolant is filtered by three steps including magnetic separation, paper tape filtering, sediment filtering two steps, cooling machine will be put into cycle use after temperature control.

● Adopt hinged carrier plate mechanism(Patent No:ZL200820052659.1), which is easy to open to make a convenient replacement and dressing of the grinding wheel..

● The machine body adopts casting boxlike structure with good shock absorption and reliable rigidity and thermal stability; Wheel heads spindle are set by vertical configuration.

Application

The device can include machining piston rings, valve gasket, connecting rod, cross shaft, valve plate, fork, hydraulic pump blade, rotor, stator, compressor vane, bearing inner and outer rings, vehicle brakes, electronic industry, magnetic ring, magnetic steel sheet of graphite plate and other products, such as:

|  |  |  |  |

| Piston ring | connecting rod | valve plate | bearing outer ring | brake disc |

Performance

Specification

Item / Type | Unit | YHDM580B |

Diameter of parts | mm | Φ12-φ120 |

Thickness of parts | mm | 0.8-40 |

Size of grinding wheel | mm | Φ585×φ195×75 |

Power of wheelhead motor | kw | 22Kw×2 |

Wheel head motor speed | rmp | 150-950 |

Feeding carrier motor power | kw | 1.5 |

Feeding carrier motor speed | rmp | 1-10 |

Plainness nd parallelism | mm | ≤0.003 |

Surface roughness | µm | ≤Ra0.32 |

Total Weight | kg | 10000 |

Overall dimensions (L×W×H) | mm | 2700×2620×2650 |

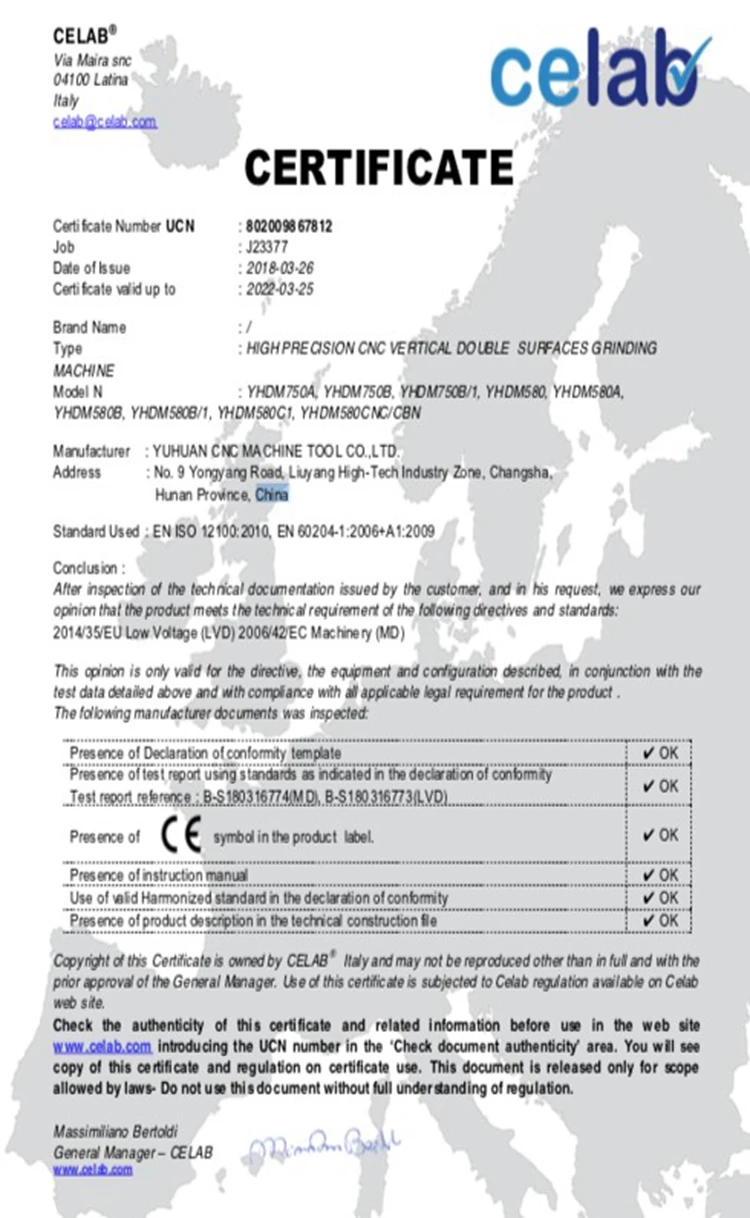

Certificate

Our R & D team establish a long - term partnership with National University of Defense Technology , Dalian University of Technology , Hunan University , Central South University , and other renowned institutions . Yuhuan is also research base for Hunan University’s doctoral student,get 5—9 patents per year .

- has got36 related patents

- A certificate of international standard products in 2005

- has passedISO9001 : 2000 international quality system certification, has estabished corporate product standards

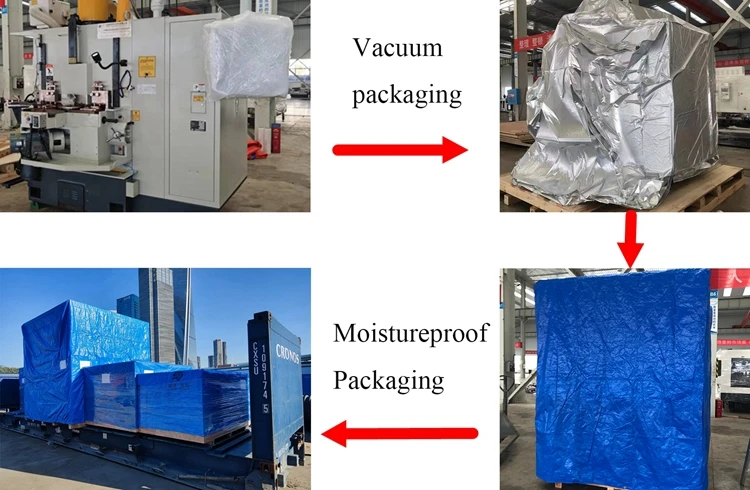

Packing and Transportation

1.Moisture-proof packaging+Wooden Box.

2.Special packing requirements available.

EN

EN  VI

VI TH

TH KO

KO RU

RU ID

ID TR

TR